Offer

Circular glasses

Material

Circular glasses are manufactured of borosilicate glass. Increased resistance is obtained by thermal prestressing.

Determination of glass thickness

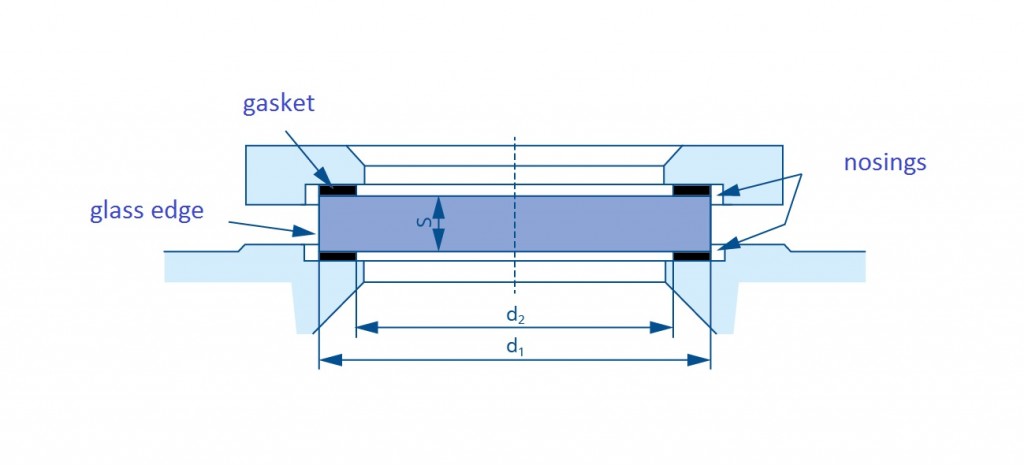

s = 0,55 ⋅dm ⋅√(p⋅S/10 ⋅ σbB]

s: theoretical minimum glass thickness (mm)

dm: average value of internal and external gasket diameter

d1: external diameter of glass and gasket

d2: internal gasket diameter

p: maximum permissible pressure (bar)

σbB: minimum bending resistance(N/msq m)

S: safety coefficient

Bending resistance

≥ 160 N/mm2

Thermal resistance

• standard: -273°C ÷ 300°C

• glasses of dimensions: 31.75×12.7 to 356°C

Thermal expansion coefficient

α 20/300≤4,3 x 10-6 x K-1 wg DIN 52328

Transformation temperature

tg = 550°C sprawdzone wg DIN 52324

Thermal resistance

• Resistance to class I acids according to DIN 12116,

• Resistance to class II alkalis according to ISO 675,

• Resistance to class I water according to ISO 719

Dimensions (mm)

| size | maximum pressure | gasket |

|||

| diameter | s | bar | d1 | d2 | thickness |

| 31,75 | 12,7 | 175 | 1) | 1) | 1) |

| 40 | 12 | 50 | 42 | 30 | 1,5 |

| 45 | 10 | 40 | 47 | 32 | 1,5 |

| 45 | 12 | 50 | 47 | 32 | 1,5 |

| 50 | 10 | 25 | 52 | 35 | 1,5 |

| 50 | 12 | 40 | 52 | 35 | 1,5 |

| 60 | 10 | 16 | 62 | 45 | 1,5 |

| 60 | 12 | 25 | 62 | 45 | 1,5 |

| 60 | 15 | 40 | 62 | 45 | 1,5 |

| 63 | 10 | 16 | 65 | 48 | 2 |

| 63 | 12 | 25 | 65 | 48 | 2 |

| 63 | 15 | 40 | 65 | 48 | 2 |

| 70 | 12 | 25 | 72 | 55 | 2 |

| 80 | 12 | 16 | 82 | 65 | 2 |

| 80 | 15 | 25 | 82 | 65 | 2 |

| 80 | 20 | 40 | 82 | 65 | 2 |

| 90 | 10 | 10 | 92 | 75 | 2 |

| 100 | 10 | 8 | 102 | 80 | 2 |

| 100 | 15 | 16 | 102 | 80 | 2 |

| 100 | 20 | 25 | 102 | 80 | 2 |

| 100 | 25 | 40 | 102 | 80 | 2 |

| 110 | 20 | 25 | 112 | 90 | 2 |

| 120 | 10 | 8 | 122 | 100 | 2 |

| 125 | 15 | 10 | 127 | 100 | 2 |

| 125 | 20 | 16 | 127 | 100 | 2 |

| 125 | 25 | 25 | 127 | 100 | 2 |

| 150 | 15 | 8 | 152 | 125 | 2 |

| 150 | 20 | 10 | 152 | 125 | 2 |

| 150 | 25 | 16 | 152 | 125 | 2 |

| 150 | 30 | 25 | 152 | 125 | 2 |

| 170 | 15 | 8 | 172 | 140 | 2 |

| 175 | 20 | 10 | 177 | 150 | 2 |

| 175 | 25 | 16 | 177 | 150 | 2 |

| 175 | 30 | 25 | 177 | 150 | 2 |

| 200 | 20 | 8 | 202 | 175 | 2 |

1) gaskets and mica for steam level gauges of high parameters

Items, for which no dimensions were provided in DIN 7080 and ÖNORM M 7353 standards, are written in bold letters.