Offer

Spiral wound gaskets

Basic specification:

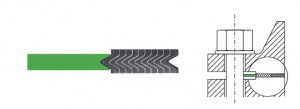

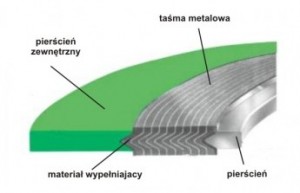

The sealing part of the Spiratem gasket consists of metal V-shape strip spirally wound together with a soft sealing filler. The metal strip guarantees excellent flexibility properties of the gasket, while pliable sealing filler ensures high sealing performance.

The sealing part of the Spiratem gasket consists of metal V-shape strip spirally wound together with a soft sealing filler. The metal strip guarantees excellent flexibility properties of the gasket, while pliable sealing filler ensures high sealing performance.

Thanks to this material combination, the spiral wound gaskets are suitable for applications requiring high pressure and temperature fluctuations of the sealed elements.

– spiral wound gaskets are suitable for a wide pressure and temperature ranges,

– spiral would gaskets are applicable for pressures from “25 MPa and temperatures from -200°C to +550°C/1100°C,

– simple construction enables easy installation without causing any damage,

– outside guide ring is used to centre the spiral sealing part against the flange and prevents the gasket from blowing out,

– by combination of various materials and metals, the gaskets are suitable for a wide range of operating conditions according to customer requirements,

– non-adhesive properties of the spiral wound gasket enable easy removal during disassembly,

– spiral wound gasket does not damage flange surfaces,

– high elasticity and reverse spring properties

Standard dimensions:

For flat flanges, groove and socket flanges, tongue and groove flanges, oval and non-standard

– EN 1514-2 (1997)

– “ASME/ANSI B 16.5 for flanges 150 to 2500 lbs – 1/2″ to 24″ according to ASME B 16.20 (1993) pressure standard

– ASME B 16.47 series A (MSS SP-44) for flanges 150 to 900 lbs – 26″ to 60″ according to ASME B 16.20 (1998)

– ASME B 16.47 series B (API 605) for flanges 150 to 900 lbs – 26″ to 60″ according to ASME B 16.20 (1998)

– BS 1560 ASME/ANSI B 16.5 for flanges 150 to 2500 lbs – 1/2″ to 24″ according to BS 3381

– DIN flanges – all types

– non-standard dimensions according to OMV, MIDER, GOST, according to customer preferences

Sealing thickness:

| Sealing thickness t1 (mm) | Tolerance (mm) | D (mm) | b max (mm) | t2 (mm) | Recommended sealing thickness upon assembly (mm) |

| 7,2 | + 0,35 | 100-3200 | 33 | 5 | 5,3-5,6 |

| 6,4 | +0,3 | 100-1600 1601-3200 |

30 25 |

4 | 4,7-4,9 |

| 4,8 (standard) | +0,25 | 15-630 631-1600 1601-2000 |

35 30 20 |

3 | 3,2-3,4 |

| 3,5 | +0,25 | 15-1000 | 25 25 |

2 | 2,3-2,5 |

| 3,2 | +0,25 | 15-1000 | 20 | 2 | 2,4-2,5 |

| 2,5 | +0,25 | 15-500 | 10 | 1,5 | 1,8-2,0 |

Standard materials:

| Material | DNI Specification | DIN material no. | AISI/ASTM | B.S. | Temperature(°C)min. max. |

| Carbon steel | RSt. 37.2 CS | 1.0038 | 238-C | 40B | -40 + 500 |

| Stainless steel | X5CrNi 18 | 1.4301 | 304 | 304S15/16/31 | -250 +550 |

| Stainless steel | X10CrNiTi 189 | 1.4541 | 321 | 321S12/49/87 | -250 +550 |

| Stainless steel | X2CrNi 189 | 1.4306 | 304L | 304S11 | -100 +550 |

| Stainless steel | X15CrNiSi 2012 | 1.4828 | 309 | 309S24 | -100 +1000 |

| Stainless steel | X5CrNiMo 1810 | 1.4401 | 316 | 316S31/33 | -100 +550 |

| Stainless steel | X10CrNiMoTi 1810 | 1.4571 | 316Ti | 320S31 | -100 +550 |

| Stainless steel | X2CrNiMo 1810 | 1.4404 | 316L | 316S11/13 | -100 +550 |

Standard fillings:

| Materiał | Temperature (°C)min. max. | pH | Application | Color labelling |

| Expanded graphite | -200 +550 | 0-14 | Aggressive environment | grey |

| PTFE | -200 +250 | 0-14 | Aggressive environment | white |

| Ceramic | -200 +1100 | – | High temperatures | light green |

| Mica | -200 +1000 | – | High temperatures | pink |

“Q” impact pressure table:

| Sealing | Pressure with external ring “Q” (N/msq m) in temperature of +20°C | Pressure with internal and external ring “q” (N/msq m) in temperature of +20°C | ||||

| min. | perm. | max. | min | perm. | max. | |

| Expanded graphite | 50 | 90 | 180 | 50 | 122 | 300 |

| PTFE | 50 | 80 | 130 | 50 | 110 | 250 |

| Ceramic | 60 | 90 | 150 | 70 | 120 | 300 |

Construction:

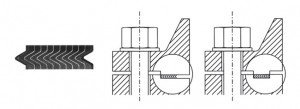

Spiratem 123

Spiral wound gasket 123 consisting of the outside centre ring, the spiral part and the inner ring (for flat flanges).

Spiratem 12

Spiral wound gasket 12 consists of sealing element and an outside centre ring (for flat flanges)

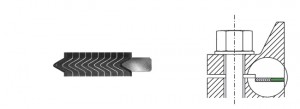

Spiratem 23

Spiral wound gasket 23 consists of sealing element and an inner ring (for groove and socket flanges)

Spiratem 2

Spiral wound gasket consists of spiral sealing and metal V-shape strip (for groove and socket as well as tongue and groove flanges)

Recommended roughness of tangential flange surfaces:

Ra=3,2 do 12,5 (μm)

Spiral wound gasket may be manufactured in oval shape. Crossbeam as presented on the figures.